The brief

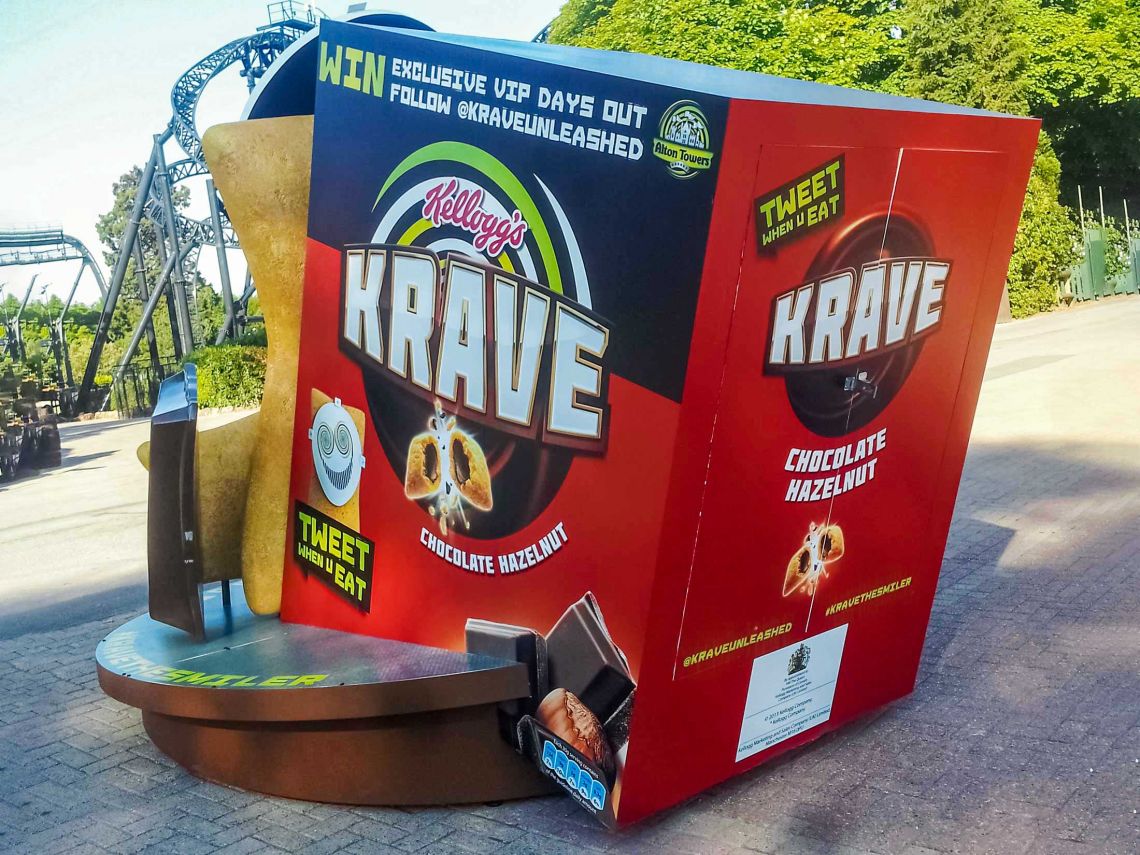

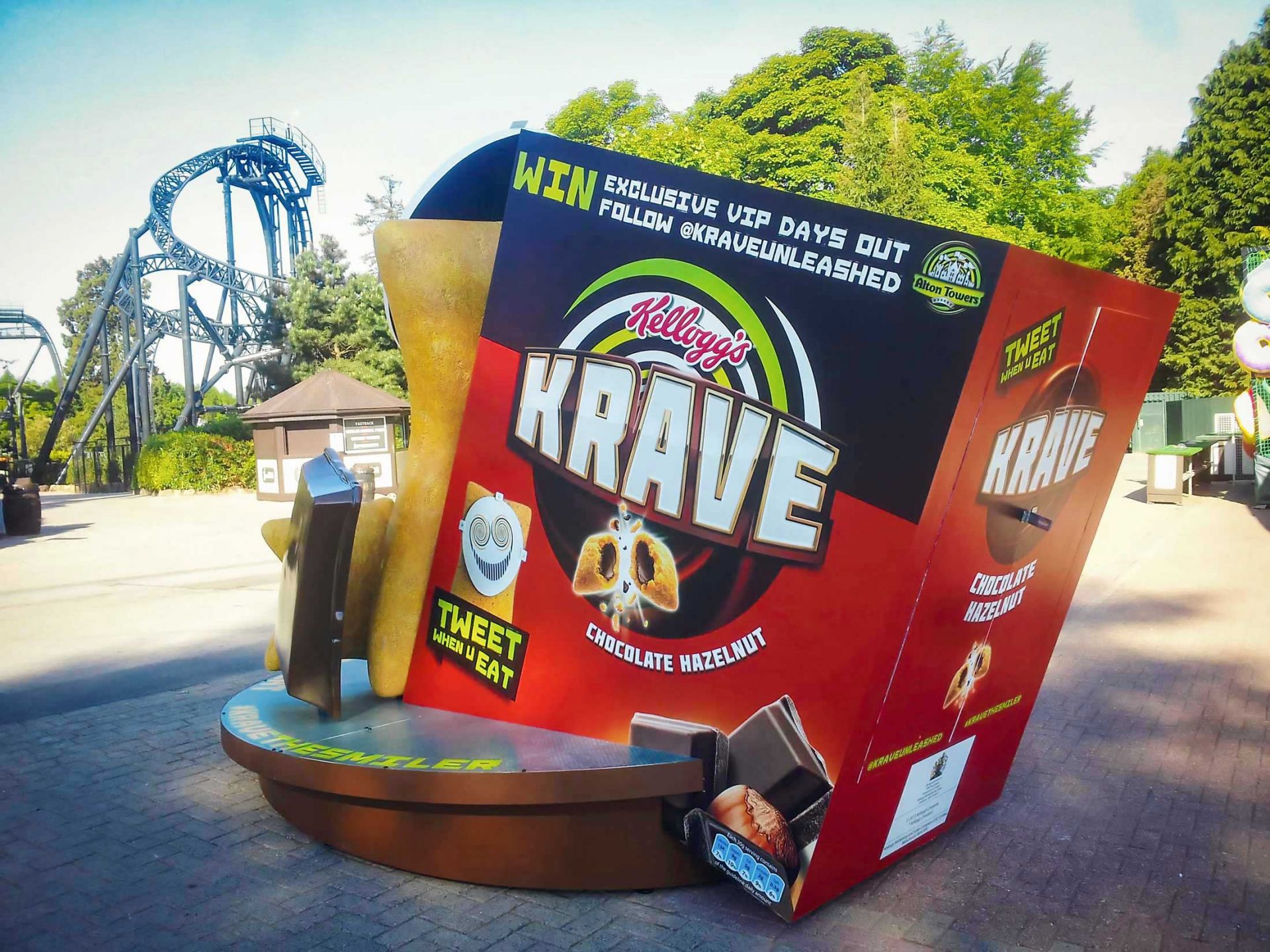

You won’t be surprised to learn that we jumped at the chance to create a giant cereal box, complete with giant cereal pieces and chocolate chunks. Don’t worry, it’s not quite as odd as it sounds. We were asked to make this giant cereal box creation as a promotion for a new ride at Alton Towers, sponsored by Kellog’s Krave cereal. So we made it, delivered it and installed it to the theme park – making sure it looked good enough to eat.

Prop process images

The Process

We needed to recreate the Kellogg’s Krave packaging exactly, as well as make oversized cereal and chocolate pieces that matched the texture of the real things – but that wasn’t our biggest challenge.

The real challenge was the complex metal work needed for the main cylindrical base that each of these giant props was going to be displayed on. Not only did it have to be structurally sound, but it also had to come apart for the ease of transportation, and then easily fit back together again.

For this project we started by drawing up AutoCAD drawings before fabricating the decking that the giant cereal and chocolate props were to sit on. Working to the exact CAD drawings made sure everything looked and worked in the way that we envisaged.

As with many of the larger structures we build, we begin with a metal armature or frame. This frame made the basis for the floor and the giant cereal packet. We clad the packet and floor with 1 marine ply and then applied a laminated printed vinyl. Because the unit was to be outside for a number of weeks everything had to be waterproof and the vinyl used was laminated with a protective lay.

We wanted the finish on the fibreglass cereal pieces to be nice and crisp so we moulded and cast them, even though there was only one of each of the pieces, but we know that a cast from a mould is way better than a coated polystyrene object because of the fine detail that is retained. Once the fibreglass pieces were made, they were tested to make sure that they fit on to the stand prior to painting.

The chocolate pieces were sprayed with lacquer to make them look glossy and to protect them from the elements.

Project Image

The Result

In the end – thanks to the team’s hard work and dedication – the complicated base of a 4 metre diameter could come apart and fit back together again seamlessly on site, and it looked great! The whole unit was displayed at Alton Towers to promote a new ride, sponsored by Kellog’s.